Better Batteries or Climate Bust

New materials are a must for a decarbonized future

by

THE NEXT-GEN BATTERIES MOONSHOT Introduced in 1991, the lithium-ion battery is the best battery the world has seen. It has transformed daily life by enabling the global spread of mobile technologies. But it will take far more capable battery technology to wean global fleets of cars, trucks, and at least some planes from their current fossil fuel diets and to fully realize a renewables-powered electricity grid. For vehicles, next-generation batteries will need to compactly store up to five times more energy than today’s technology. For storing and dispensing grid-scale electricity generated from wind and the sun, next-generation batteries also will have to be massively and affordably scalable. A rollout of such storage technologies could herald an “electrify everything” society that dramatically cuts carbon emissions and heads off disastrous climate change.

THE PHILANTHROPY OPPORTUNITY Battery technology improves at a glacial pace. In 28 years, the energy packed by a typical lithium-ion battery has increased only by a factor of three. Advances in materials and computational science are now enabling researchers at national labs and universities to simulate, produce, and test potential new materials for batteries at an unprecedented pace. But moving even the most promising new materials from discovery to prototype to commercial products to large-scale deployment will require substantial and patient financial support. Philanthropic funding could play a critical role in bridging the dreaded “Valley of Death” that kills off most high-tech development projects by giving ambitious, entrepreneurial battery innovators a sufficiently long runway to develop and deploy potentially world-changing energy storage technology.

The numbers are in, and they are a call to action: Today’s fossil-fueled culture could warm the planet by 1.5º C (2.8º F) or more. That’s a temperature rise scientists believe could usher in a future of rising sea levels, supersized storms, and droughts that demolish crops and set off famines at unprecedented scales.

The solution seems straightforward: decarbonize the economy. That means electrifying everything — from cars, trucks, boats, and planes to home heating and cooking. It also means generating that electricity from carbon-free sources such as wind turbines and solar panels — two technologies that are widely available and getting cheaper fast.

Yet in that statement lies a hidden technological challenge that could be far more difficult to overcome: how to store renewable energy when it’s generated and deploy it when it’s needed on the grid, on the road, and in the air. The world’s best electrical energy storage device is the lithium-ion battery, a miracle of materials science. But today’s lithium-ion batteries are far too heavy and slow-charging for a global redo of cars, trucks and planes, and far too puny for the electrical grid. We need dramatically more capable batteries.

Adding to the challenge is that one type of battery won’t do the entire trick. For transportation — the source of almost one-third of U.S. carbon emissions — a battery must pack immense amounts of energy into small spaces, release that energy as needed, and quickly recharge thousands of times without breaking down.

For the grid, which accounts for another near-third of emissions, something else entirely is needed: a battery that can scale up enough to store electricity generated by millions of wind turbines and vast expanses of solar cells. According to one estimate, doing that for just the United States with today’s batteries would cost an economy-busting $2.5 trillion.

To invent the new battery technology the world needs, researchers must dive deep into the atomic constructions — the materials — at the heart of batteries. They need to find new materials that can outdo known ones. It’s a moonshot project with next-generation battery technology in its sites.

“Materials are tricky beasts,” says Kristin Persson, a materials scientist at Lawrence Berkeley National Laboratory in California. “Materials development takes patience and time and money.”

Battery technology is notorious for its maddening insistence on tradeoffs. Find a way to crank up the amount of energy a battery can store and you are likely to reduce its service lifetime or make it unaffordable. Pump up the rate at which a battery can discharge its power and it might become too likely to explode or catch fire.

“We have to satisfy multiple performance metrics simultaneously,” says George Crabtree, a physicist at Argonne National Laboratory (ANL) in Lemont, Illinois.

Despite this tyranny of trade-offs, a can-do community of materials scientists, physicists, and chemists is convinced it can deliver the batteries the world needs. Researchers around the globe are racing to mix-and-match atoms in novel ways that will unlock world-record energy-storage capabilities in practical and affordable batteries. The U.S. Department of Energy (DOE) recently committed $120 million over 5 years to the Joint Center for Energy Storage Research (JCESR), headquartered at ANL just west of Chicago, for this purpose. JCESR’s post-lithium-ion R&D effort is among the largest in the world, supporting more than 150 researchers at 20 institutions. Germany and the United Kingdom host complementary efforts, as do numerous private companies.

Discovering new materials with properties suited for a particular application is just the start. A candidate material must also be tested extensively and developed so that it can be incorporated into a practical manufacturing process. And it must show an overwhelming advantage over what’s already available. Getting through this gauntlet of requirements and all the way to large-scale commercial production requires an innovation ecosystem, including venture capitalists, startup companies, battery manufacturers, and finally the Teslas, Apples, and Duke Energies of the world that comprise the huge end markets for these technologies.

Ushering a new material from discovery to commercialization takes, on average, 15 years and enormous up-front costs, says Persson. This is because a material can fail in myriad ways — it can be too expensive, require rare ingredients with conflict-ridden supply chains, break down too readily, or be too flammable or toxic. That’s why so many materials discoveries die early.

Those that survive must then traverse the infamous Valley of Death that quashes most technology ambitions before they can succeed commercially. Even the lithium-ion battery almost died at this stage. Exxon filed the first patent in 1976 but did not advance it to the finish line. It was later embraced by Sony, which within 15 years used it to launch a new generation of video cameras. The lithium-ion battery market now tops $30 billion.

“Materials are tricky beasts. Materials development takes patience and time and money.” — Kristin Persson, Lawrence Berkeley National Laboratory

As Persson’s colleague Gerd Ceder put it in an interview with MIT Technology Review: “Even if I had something that worked perfectly in the lab today, you would probably have a six-to-10-year slog” to get it to market.

But there are reasons to believe the search for better battery materials and technology is poised to accelerate rapidly. With powerful new computational methods, researchers can now screen thousands of simulated candidate materials for specific technological applications, including batteries. The best candidates get produced in the lab and tested. And some are outperforming any material previously dreamed of.

“Five years ago, everyone was skeptical. They said, ‘Show me something on a computer that I couldn’t have predicted myself,’” says Crabtree. “I don’t think there were many good examples. Now there are.”

Battery Science 101

Almost all batteries harness an electrochemical cell consisting of three main components. At the anode, a chemical reaction liberates electrons that flow through an external circuit and power electrical devices. At the cathode, a different electrochemical reaction recovers the electrons. Between the anode and the cathode is an electrolyte — a liquid or solid substance through which positively charged atoms (ions) move from the anode to cathode, thereby balancing the electrons’ negative charges. In the lithium-ion batteries powering your computer, smartphone, and perhaps your Tesla or Chevy Bolt, the anode is made of a form of carbon called graphite (possibly with a bit of silicon), the cathode typically consists of oxides of cobalt and other metals, and the electrolyte is a lithium salt through which the charge-balancing lithium ions move.

Since Alessandro Volta invented the electrochemical cell in 1800, only a handful of battery chemistries have been deployed on an industrial scale, including lead-acid, alkaline, and lithium-ion. The last of these, which keeps its weight and volume low by relying on the third lightest element on the Periodic Table as the charge carrier, has become the dominant technology for many applications. Apart from the occasional headline-grabbing battery fire, lithium-ion batteries are safe and can withstand thousands of charge-discharge cycles.

“It’s by far the best battery we’ve ever had,” Crabtree says.

He did not say it is the perfect battery. For one thing, the cathodes and anodes of lithium-ion batteries are built around scaffolding materials that add bulk, limiting how energy-dense the batteries can be. “Separators” that protect the electrodes from degradation add further bulk; still, as anyone who owns a laptop or cell phone knows, battery lifetime withers within a few years. Moreover, the cobalt needed for the cathode is expensive and is mined mainly in the Democratic Republic of Congo, a country rife with human rights abuses.

It has proven maddeningly difficult to improve lithium-ion batteries. True, their energy densities are about three times higher than their forebears in 1991, when Sony rolled out the first commercial cells in its groundbreaking Camcorder video camera. But that uptick for a pivotal battery trait is a pittance compared to other technological gains over that period. The number of transistors on an integrated circuit chip has increased 10,000-fold since 1991, for instance, enabling the mobile revolution and relentless advances in computational science and computer simulation.

The intransigence of batteries to rapid improvement led the DOE to launch JCESR in 2012. Its initial five-year goal was to nurture new battery concepts to a point that commercial developers would want to pick up the baton and run with the technology to the finish line. So far, the center’s researchers have produced four prototypes. One of these has spawned a startup company — Cambridge, Massachusetts-based Form Energy — which is seeking to produce a new kind of battery for the electric grid.

But Crabtree and his colleagues realized their other battery prototypes stood little chance of overhauling the technology enough to decouple transportation and the electrical grid from fossil fuels. So for its next round, JCESR has taken on a more difficult charge: Come up with new game-changing battery materials.

On the transportation side, energy density is the number one problem. To move a car 300 miles or more between charges — what we expect from our gas tanks — today’s vehicle battery packs bulk up to more than 1,000 pounds and cost around $15,000. In addition, these battery packs take up to 8 hours to charge, and cars powered by them might lose 40% of their range on a cold winter day. Some early adopters have taken a chance on the available electric cars, but the vast majority of new vehicles still burn gas. A future with electric-powered aircraft that zip within and between cities — something Norway has said it wants by 2040 — will require even more lightweight and energy-dense batteries. An Israeli company has promised an electric nine-seater aircraft by 2022, but its range will be less than 700 miles and its battery will account for more than half the weight.

Here’s one reason no one has discovered the secret to massively better batteries: There are infinite ways to combine the chemical elements into potential new materials. Yet for batteries nearly all of these combinations will succumb to the tyranny of trade-offs by falling short due to insufficient energy density, charging speed, safety problems, lack of durability, or some other showstopper. But Crabtree, Persson, and their colleagues are leveraging advances in computing power that enable them to rapidly explore vast regions of the materials landscape and probe in quick succession the potential of tens of thousands of simulated materials.

As a graduate student, Berkeley Laboratory’s Persson says, simulating a single material’s properties might have required up to a year’s worth of computing. Now, by combining a well-honed method called density functional theory (DFT), which deploys quantum mechanical analysis to reveal a simulated material’s potential properties, with ultra-powerful supercomputers, she can partner with her computers to identify and, in mere weeks, vet thousands of novel material structures that stand chances of becoming key ingredients for next-generation batteries.

Recently, Persson wielded the simulation powers of the Berkeley Lab’s Energy Research Scientific Computing Center to investigate materials for a magnesium-ion battery. Like lithium ions, magnesium ions are lightweights of the Periodic Table, but they carry two positive charges compared to lithium’s one, potentially delivering twice the electric current per atom. Magnesium metal is also far less chemically reactive than lithium, which means battery designs could feature pure magnesium anodes without having to add the graphite used to keep lithium’s reactivity in check. Magnesium is also 3,000 times more plentiful than lithium in Earth’s crust. Imagine your phone running for a week on a single charge, or an electric vehicle comfortably zipping from D.C. to Boston without stopping, or a commute by electric air taxi — that’s the promise of a magnesium battery.

But nothing in battery design is easy. Magnesium ions get stuck in existing cathode materials like the cobalt-oxide used for lithium batteries, for example. In an effort to solve that problem, Persson used her DFT-powered computer simulations to identify so-called spinel materials, the interiors of which would feature microscopic pathways for the ions.

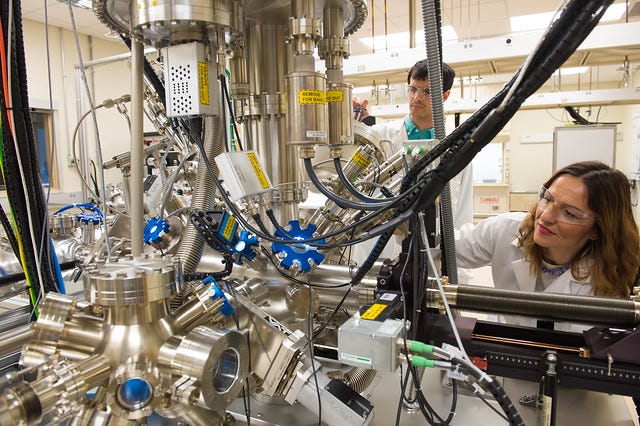

She handed off her best computer-based leads to members of the team of materials scientist Brian Ingram, who heads JCESR’s new materials discovery program at Argonne. He made samples of the spinel materials, packaged them into coin-sized cells with anodes and electrolytes, and tested them. Ingram confirmed that magnesium ions could repeatedly enter and exit the spinel cathodes as the cell discharged and recharged. That’s a crucial step toward a viable post-lithium-ion battery, he said.

But the success has brought to the fore a new challenge: The high voltages enabled by the novel cathode causes the electrolytes they’ve been using to break down. Next on the agenda: a new magnesium battery electrolyte.

Despite the challenges, Persson is bullish on developing a magnesium-ion battery candidate as a candidate for a far more electrified future.

“As a scientist,” she says, “I try to be optimistically cautious.”

Batteries on the Brain

Supercomputers are rocketing the pace of materials discovery for batteries, but it takes human scientists’ imaginations to come up with ideas like using air as a potentially transformative battery ingredient.

Twenty-file miles northeast of Argonne’s state-of-the-art facilities, Amin Salehi-Khojin, a professor of engineering at the University of Illinois at Chicago runs a humbler operation. Salehi-Khojin is betting on what many scientists view as a dark horse: a lithium-air battery. He wants to keep using lithium, but to design a cathode to take advantage of a chemical reaction that lithium can undergo with oxygen molecules to form a compound called lithium peroxide. This compound sports a type of chemical bond (covalent) that can store lithium’s electronic energy more compactly than independent lithium ions intercalated within metal oxide layers. The oxygen would come from plain old air, which would flow into the battery from outside. The design would do away with the bulky scaffolding current batteries need to hold lithium ions, potentially allowing for a sub-featherweight cathode. According to Salehi-Khojin, such a battery would provide “the highest energy density we can imagine” — possibly three to five times higher than today’s best lithium-ion batteries. That could be a game-changer for electric vehicles and enough of a technological leap to launch electric flight.

But Salehi-Khojin faces the tradeoff conundrum, too. ANL researchers had determined that a lithium-air battery would break down quickly due to reactions between battery components and air’s non-oxygen constituents — mainly carbon dioxide and water. Getting such a battery to work, therefore, would require outfitting vehicles and other devices with bulky and dangerous tanks of pure oxygen to flow through the batteries, the ANL researchers reported. “That scared people away,” Salehi-Khojin told The Moonshot Catalog.

It didn’t scare Salehi-Khojin away. In previous research, he had used a compound called molybdenum disulfide as a catalyst in an “artificial leaf.” He realized he could repurpose the substance as a battery cathode to catalyze a handy reaction between lithium and oxygen in a properly designed lithium-air battery. He then developed a lithium carbonate coating to protect the lithium anode from reacting with the air molecules. Lastly, he applied his materials science finesse to the electrolyte, brewing up a mixture that shuttled ions while keeping the problematic air constituents from causing trouble. In a crowded basement lab where white-coated graduate students deftly manipulate various battery manufacturing and testing devices, Salehi-Khojin and his team assembled the materials into a test cell. They were shocked to find that it not only worked but lost little capacity after 700 charge-discharge cycles.

Colleagues skilled in computational analysis, electron microscopy, and other materials-analysis techniques helped improve the design by revealing details about how the new battery was working or falling short. In 2018, the team published their findings in Nature. The result almost single-handedly revived hope for a lithium-air battery, Crabtree says.

Even so, the Samsungs and Panasonics of the world are not beating down Salehi-Khojin’s office door. For that to happen, he and his colleagues need to make more improvements such as raising the operating voltage, combining cells into prototype systems, and demonstrating that these work under punishing real-world conditions. Salehi-Khojin admits he’s unsure about what the best path forward is — whether to found his own company, or try to hand off his laboratory success to someone with experience in bringing technology to market.

“This next step is very risky” and expensive for a would-be developer, says Larry Curtiss, a materials scientist at Argonne who helped Salehi-Khojin with calculations. It would mean producing and testing many different battery configurations to find one that works, and that requires specialized equipment and expertise not contained in most university research groups. “If we had a prototype that worked, then going to the actual battery pack would be easier,” Curtiss says. “But between the lab and the prototype — it’s hard to find funding for that.”

Starting up

On those rare occasions when a battery design proves successful enough to attract investors and move out of the lab, startup companies like Chicago-based Nanograf take the next difficult steps. The firm occupies two windowless offices and a modest lab space that doubles as a miniature battery production line in a technology incubator “park” established by the Illinois Institute for Technology. Founded as SiNode in 2011 by battery entrepreneurs Samir Mayekar, Cary Hayner, and Josh Lau, the company’s technical foundation began taking shape even a few years earlier in the form of a research project at Northwestern University. Mayekar and Hayner planned to change how the industry makes batteries, but they hit barriers, not all of them technical. For one, they were cash strapped. That limited the research they could afford. Another reality check was that battery companies were not looking to upend their time-tested manufacturing lines; they wanted something they could just drop into their existing equipment and battery designs.

Then a scary thing happened: A123, a Massachusetts-based company that received torrents of capital and media attention and became a darling of the Obama administration, went bankrupt in 2012. The company had built more manufacturing capacity than it had demand for its products and it suffered a costly battery recall. The high-profile failure sent a chill through the battery-startup world and made venture capitalists wary of funding other would-be transformers of battery technology.

Hence the scrappiness of the Nanograf facility. During a tour, Hayner, now the company’s chief technology officer, showed off one room where he and his team mix battery materials and coat them onto copper foil. In the next room were fridge-sized testing units holding around 500 coin-sized cells, each one coursing with calibrated electric current across the cells’ electrodes.

Nanograf’s near-term goal is to redesign the lithium-ion battery anode by replacing much of its graphite with silicon. A silicon-based anode could, in theory, hold 10 times more lithium ions by mass than the graphite sheets or rods currently in use. And that could give batteries a meaningful, if not revolutionary, bump in energy density of about 50%. But when a silicon crystal takes in lithium ions, it swells; when it releases the ions, it shrinks. Hayner compares it to an inflating and deflating balloon. The swelling and shrinking eventually cracks the crystal — a ruinous property for a commercial product. This is why Hayner and his company colleagues have opted for a hybrid anode design with up to 30% silicon. In contrast to the computational searches by the Argonne researchers, the Nanograf team spends a lot of time physically mixing silicon and graphite in hundreds of combinations in search of an optimal anode material. A win would be a material that can significantly boost a battery’s energy density while also being tough or flexible enough to handle the in-and-out cycling of the lithium ions.

With this hands-on approach, Nanograf has produced cylindrical battery cells of the form Tesla puts in the battery packs for its cars. To try to get the attention of Tesla or similar potential customers, Nanograf recently partnered with a Tokyo-based manufacturer, JNC Corporation, which is scaling up Nanograf’s top battery contenders. Potential customers are now putting the cells through rigorous testing. Investor money and patience is limited, however, so the Nanograf team needs their prototype batteries to pass the tests and then move further along the pathway to commercialization. The 8-year old company has yet to turn a profit.

So far, Nanograf has managed to stay alive in its already long trek in the Valley of Death. The question is whether Hayner and his team can negotiate enough of the tradeoffs in battery-tech development before they run out of money.

“Investors want returns in less than 10 years. That puts constraints on how revolutionary we can be,” Hayner says. With more patient support, he argues, the company would be able to push their current technology-development trajectory toward even more ambitious endpoints, meaning next-generation batteries that can make even more of a difference. Says Hayner, “I think that is something that is missing: people who are willing to think slightly longer term.”

Storing the sun and the wind

Arrays of cells packing next-generation battery materials may power tomorrow’s transportation vehicles. But truly massive batteries will be required to manage the ebbs and flows of power generation in a national-scale electrical grid driven chiefly by renewable power sources. Developing these will take a different kind of imaginative leap. It will take megawatt-scale thinking and doing to get the electricity grid off of its fossil fuel addiction. For the first time, this is a real possibility: Solar and wind power have fallen rapidly in price, becoming cost-competitive with fossil fuel power generation. Combined, solar and wind recently overtook hydropower as the U.S.’s fourth-largest source of electricity after gas, coal, and nuclear.

But two basic problems loom over a clean-energy future: The sun doesn’t always shine, and the wind doesn’t always blow. Without a way to store energy for when it’s needed, renewables’ vast potential will remain largely unrealized. Gas and coal plants would likely have to continue to power the grid at night, on windless days, and during periods of peak demand.

Massive batteries could, in theory, provide that stop-gap storage, soaking up wind- and solar-generated electricity when the generating is good, and feeding it back onto the grid when it’s not. “You can have power at your beck and call when the sun isn’t shining and wind isn’t blowing,” says Michael Perry, an engineer at the Connecticut-based company United Technologies Research Center.

Moreover, unlike in-vehicle batteries for transportation, grid-scale batteries need not be particularly energy dense, because once installed, they won’t move. In fact, utilities have recently begun to experiment with trailer-sized lithium-ion battery arrays: A Los Angeles utility installed a 70-megawatt system to replace gas “peaker plants” that kick in during heavy periods of demand such as on hot days when thousands of energy-hogging AC units roar to life. The big battery has worked for 2 years and counting. “That has given people confidence,” says Crabtree. In South Australia, Tesla has installed a 100-megawatt grid battery. Dozens of new projects have been announced — most recently, a major solar project in southern California that will be armed with an 800-megawatt-hour battery that promises to reduce the cost of electricity generation below that of a comparable fossil-fuel plant.

But if it is tasked to provide baseload power, rather than just an extra boost on top of fossil fuels or nuclear, lithium-ion technology runs into a mega-problem: It doesn’t scale well in the context of the entire electrical grid. If you simply bulk up the battery components, the ions cannot penetrate deep into the electrodes and the overall energy density plummets. And everything about the grid is about scale. Power-plant-scale batteries will need to store and release huge quantities of energy for up to 16 hours at a time — the long wait between sunset and sunrise on a winter day in the United States. That’s a far cry from the minuscule power needs of handheld devices for which lithium-ion batteries were designed, and even from the relatively modest needs of vehicles. Current grid-installed lithium-ion systems tap out after around 4 hours, making them good for adding a bit of juice during peak energy-demand periods, but not much else. There’s also the issue that electric vehicle battery electrodes are already gobbling up much of the world’s cobalt and lithium supplies.

The leap beyond the lithium-ion standard for grid applications could end up taking the form of what insiders call a “flow battery.” A flow battery is essentially a miniature chemical plant, with two side-by-side tanks of chemicals dissolved in solvents, usually water. Between the tanks is a semi-permeable membrane. On discharge, a chemical reaction between two reactants in one tank releases electrons that flow through a circuit as positive ions in the mix traverse the membrane to balance the electrical charge of both tanks. On recharge, the reaction reverses. There are no expanding and contracting anodes and cathodes to wear out over time. In theory, such batteries could be scaled up indefinitely — just increase the volume of the tanks — and they should be able to run for decades.

As so often is the case in battery development, the right materials for grid-scale flow batteries are lacking. Adding to the challenge, says Perry, is the nascence of flow-battery R&D. There wasn’t a business case for it until a few years ago, when renewables started hitting the market in a major way. “Nobody cared,” about flow batteries, he says, “because you weren’t going to put them in a laptop or a car.”

Most current designs are based on vanadium metal, which is unique among metals due to its unmatched flexibility in picking up and shedding electric charges. So far, vanadium’s high price has relegated such batteries to niche status; some have estimated that running the grid off of them would cost more than the estimated $2.5 trillion a lithium-ion-based option would cost. But other experts see the beginnings of an economy of scale that could bring the price down rapidly.

Furthering that cause is the Massachusetts-based startup company VIONX, which now is attempting to commercialize one of Perry’s company’s designs. Toward that end, it has installed a pair of vanadium-based flow cell systems in Shirley, Massachusetts, next to a large solar cell array where the batteries can store 500 kilowatts of electricity for 6 hours, according to VIONX’s website.

Now, flow-battery researchers are trying to make up for lost time. Form Energy, the JCESR spinoff which counts former executives of A123 among its leadership, is trying to develop a flow battery based on the abundant element sulfur. That approach could slash the cost per energy stored to a fifth of today’s vanadium units, according to MIT Technology Review.

At JCESR, researchers are investigating a different, possibly more radical concept. They are using their computational tools to search for a vanadium substitute in flow cells in the form of electrically-active organic polymers — chain-like molecules made of cheap, abundant carbon, hydrogen and oxygen atoms.

There is an infinitude of possible polymers to consider. So identifying ones with the right properties and performance falls into the needle-in-haystack category of searches. “The good news is that there are lots of options,” Perry says. “The bad news is that there are lots of requirements.”

That, says Crabtree, makes the problem ripe for analysis using the computational discovery toolbox. In particular, he sees potential for one of the newest tools: machine learning, a method that excels at finding hidden correlations in enormous datasets such as ones associated with the vast organic molecule space. Recently, in JCESR-funded work, a machine-learning algorithm discerned structure-function correlations by analyzing a pile of organic molecule structures and then predicting an ultra-stable flow-battery material candidate that no human had ever thought of. A University of Michigan researcher produced and tested the material and it lasted 1,000 times longer than the current best-in-class for organics.

That accomplishment “caught our eye,” Crabtree says. But without further development, the material would still not be stable enough for building a massive, long-lasting infrastructure of flow batteries to provide the reliable electric power we’re used to and that the power industry demands. Solving these problems now has become the task for Crabtree and his coworkers. With only 4 years of funding left and no more renewal grants possible, the task is urgent.

Patient money needed

Currently, the Valley of Death remains ruthless for battery technology visionaries. The U.S. government has generally supported basic research, JCESR being a prominent example, and as of this writing, Congress is considering at least five energy-storage-research-related bills. But governments are often less keen to fund the later prototyping and development phases, for fear of stepping into industry’s turf. Industry, on the other hand, wants something close to a sure bet before investing. Yet a vast chasm yawns between a battery technology concept that can be made to work in a lab and a robust, practical, manufacturable, scalable, and affordable device that performs day-in and day-out for years.

Venture capitalists can often shepherd innovators partly across the Valley. But they like return on their money within a few years, Persson says, and materials-centric innovation almost always takes much longer. “If you come to them and say you’re going to be in the materials business, they don’t want to fund you,” she says.

Breakthrough Energy Ventures, a prominent venture capital fund with money from Bill Gates, Michael Bloomberg, and other billionaires, is perhaps the best example of a fund seeking to bridge the Valley. It currently funds three battery-related startups. But only one, Form Energy, is seeking to design a post-lithium-ion battery, with the help of $9 million it received from the fund as well as support from other sources. One of the Breakthrough-funded startups is not even pursuing a new battery design at all; it’s searching for new sources of cobalt to open up more production of existing technology.

“When you need real breakthroughs, you have to just fund creative individuals and let them do their thing.” — Marc Kastner, Science Philanthropy Alliance

Marc Kastner, a materials scientist who once chaired the Massachusetts Institute of Technology’s physics department and now heads the Science Philanthropy Alliance — which seeks to guide philanthropists’ investments in basic research — also sees a role for investment when a new technology is just a glimmer in some scientist’s eye.

Philanthropy has a track record in the physical sciences of funding concepts that are too high risk for other kinds of funders, Kastner says. For example, Bill Gates, Eric Schmidt (whose philanthropy, Schmidt Futures, supports The Moonshot Catalog) and others provided more than $30 million in seed funding for a radical new mirror design for the Large Synoptic Survey Telescope. That early support enabled the telescope’s champions and designers to prove their idea was solid enough that the National Science Foundation became willing to invest in the project. The LSST is slated to begin operating by 2023.

“The huge advantage that philanthropists have is that they can take risks and they can act more quickly” than government agencies, whose peer review processes and Congressional oversight often mitigate against risk-taking and innovation despite funders’ best intentions, Kastner says.

Unfortunately, materials-based innovation, despite its potential for major societal impact, has a hard time attracting philanthropy support, Kastner has found.

To Kastner, this means philanthropists could fill an important niche by, for example, funding the creation of an institution for materials science that gives researchers the resources and time they need to make big differences. Such an institution might resemble the Howard Hughes Medical Institute, which gives selected biomedical researchers $8 million and 7 years before they go up for review.

“When you need real breakthroughs, you have to just fund creative individuals and let them do their thing,” Kastner says.

Real breakthroughs in battery tech: That’s part of what it will take to shift from a fossil-fueled present to an electrified, decarbonized and more survivable future.

is a freelance writer based in Mount Rainier, Maryland.